Double-Sided Material Processing

Material Processing – Laser Cutting Solutions

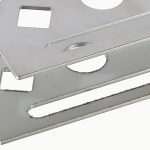

To further support our fabrication process, Unique Metals Laser have invested in the latest metal processing technology. The highly effective double-sided material processing of both inside and outside contours of steel, stainless steel, aluminium in just one single pass.

In the area of surface treatment and material processing, be it oxide film removal, deburring, or grinding, this technology is able to provide a high standard of productivity offering clients viable solutions to their production needs.

The Lissmac brand dates back to 1979 and since entering the sheet metal back in 2003, they have set the bench mark for edge rounding machinery.

Supporting Australian manufacturers nationally for over 50 years, Unique Metals Laser are a valued provider of high-accuracy cutting, perforating, forming, folding and fabricating services to the steel industry.

Unique Metals Laser pride ourselves in providing valued solutions to meet our clients production requirements and are committed to servicing our clients while supporting them in achieving their objectives from each of our separate sites.

Utilising the latest equipment through our sites we’re able to provide. Laser Cutting, Plasma Cutting, 3D Tube Laser Cutting, Turret Punching, Folding & Fabrication services.

Delivering quality products and service to our clients is our goal to ensure your experience, is a uniQue experience.

If you’re looking for Metal Laser Cutting/Tube Laser Cutting/Steel Laser Cutting/Stainless Steel Laser Cutting. 3d Laser Cutting/CNC Laser Cutting/Aluminium Laser Cutting/Plasma Cutting/Turret Punching/Folding/Fabrication services, then we can assist.

Contact our friendly and helpful team. We’re here to support you!